Inquiry

Online-application

Ottobock Science Center, Berlin

VITERRA Development

Owner / Developer

Otto Bock HealthCare

Architect

Gnädinger Architekten

Building Function

Competence Centre for Health Care Technology

Status

Completed 06/2009

approx. 1.500 m²

Height

approx. 22 m

Technical Features

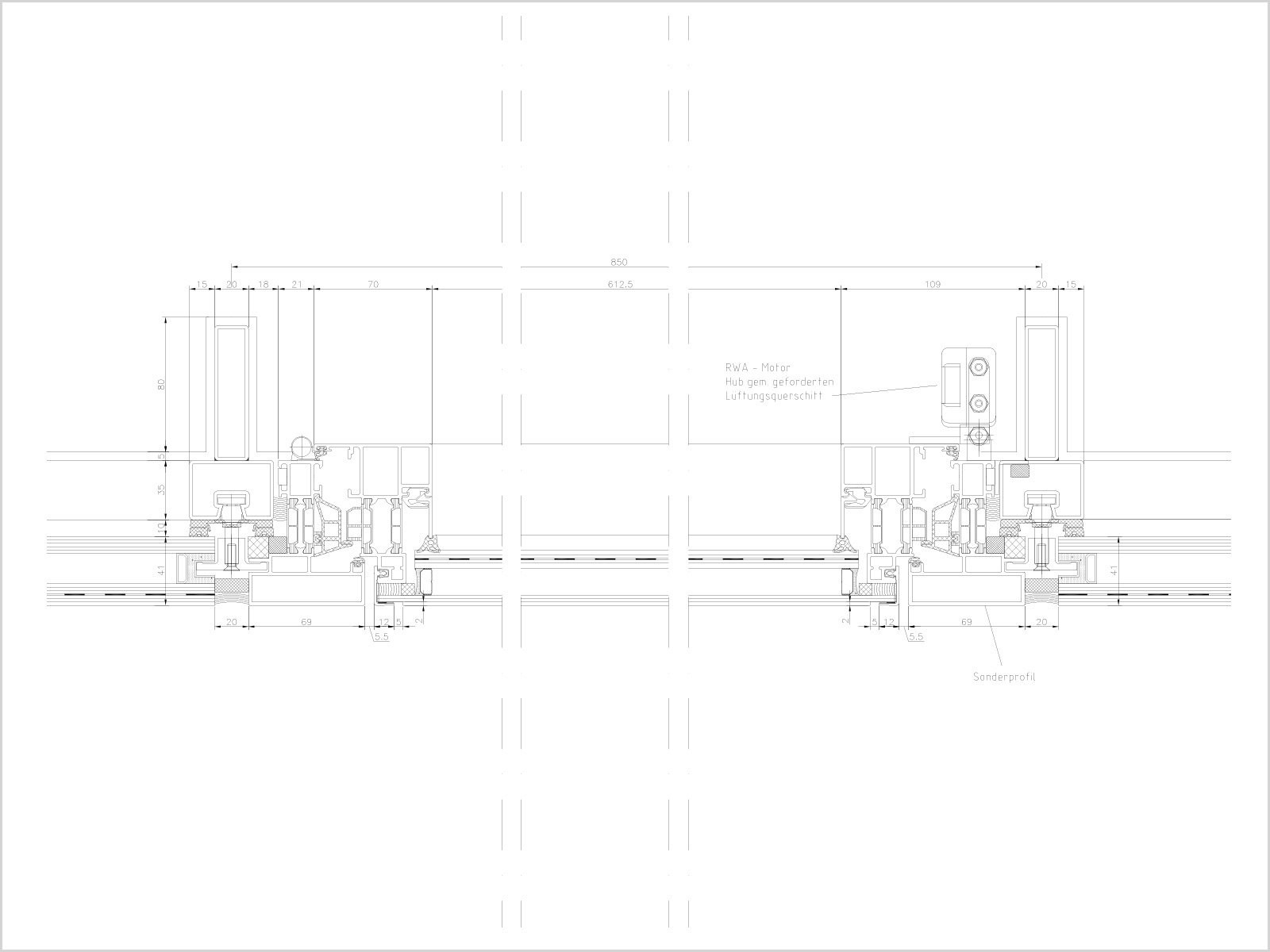

- Stick system facade, straight mullions, curved transoms, aluminium

- Structural glazing facade, partly curved

We provided

Consultancy

At Priedemann any project starts with the determination of the planning basis, with the facts, requirements and possibilities – no matter when we start and always together with everyone involved in the project

- What is the design concept?

- Which local standards apply?

- Urban planning requirements?

- Energy requirements?

- Weighing up the priorities in the “magic triangle” of quality, costs and duration

- Definition of an objective as a benchmark for all subsequent planning phases

- Development of the evaluation criteria as expert assessors in architectural competitions

We design different variants based on the strategic objectives, we identify their advantages and disadvantages and keep on developing the preferred solution.

- Sketches of concepts drawn by hand

- Taking into account different options for materials and the construction

- Inclusion of structural and thermal loads

- Dependencies in the building structure are taken into consideration

- The physics of the building and acoustic requirements are taken into consideration

- Fire protection and smoke extraction are taken into consideration,

- Cleaning and maintenance plan, access at heights

- Outlining solutions, costs and timings

- Inclusion of existing solutions to clarify the design

- Support during the initial sampling

- Documentation in report form

- Ongoing updating or further development of the design

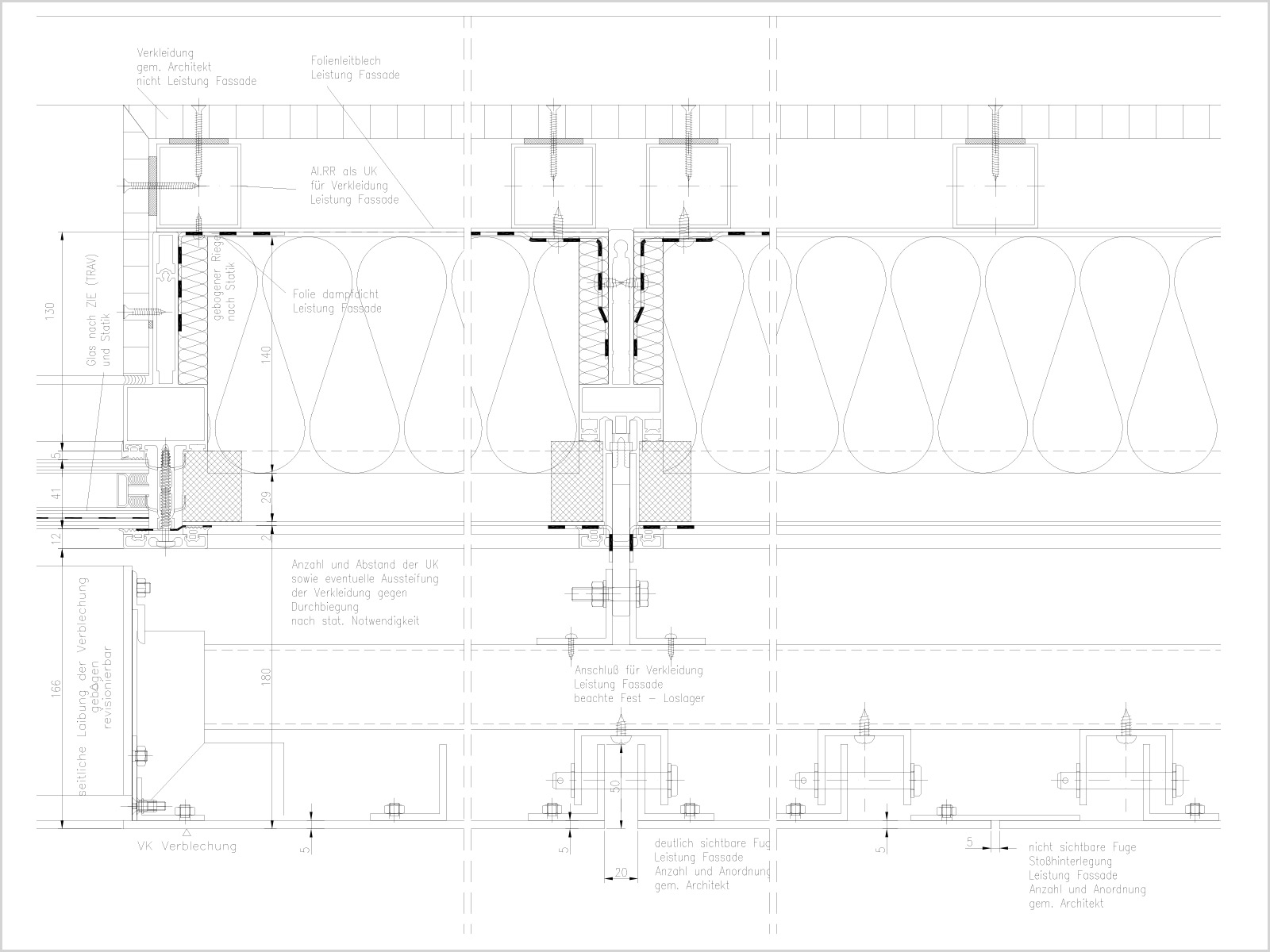

Priedemann sees the implementation planning as a precise simulation of the construction process and the building – in detail, digitally and, depending on the complexity, as a 3-dimensional model.

- Guide-detail planning as CAD drawing on a scale of 1:1 with all connections to adjacent components

- Detailed representation of the layers, components and individual components of the facade solution supplemented by material descriptions and dimensioning

- Planning on the basis of static pre-dimensioning for the relevant facade components – glass, profiles, fixings

- Advanced planning for the building physics and acoustics

- The specified security and fire safety requirements are taken into consideration

- Planning and integration of control and operating components

- Updating costs and the construction schedule

- Agreed plan for the materials

- Glass specifications

For tendering and awarding contracts Priedemann defines and specifies the planned facades and details as well as the connections to adjacent components.

- Summary of technical requirements as well as client and user specifications for construction and materials as “Technical Preliminary Remarks”.

- Compilation of the design and additional technical criteria in coordination with the planning team

- Drafting of the service description

- Individual quantities and components are recorded

- Differentiation of the various trades when awarding contracts to different contractors, clear definition of the interfaces

- Collation of all documents in a single set of documentation

The supervision of assembly and installation is particularly important for us, to ensure the agreed quality. Our principle is that deviations from the agreed planning must be identified at an early stage, documented and the implementation corrected. This controlling refers both to production and manufacturing as well as to the assembly on the building site:

Regular inspection of production and assembly in the factory- Verification of compliance with the approved design, ensuring compliance with the agreed qualities, standards and test series

- Regular reporting on production progress; the reports contain recommendations for possible improvements as well as a list of unfulfilled services, performance arrears, defects identified

- Verification of compliance with the approved design, ensuring compliance with the agreed qualities, standards and test series

- Inspection of examples of facade sections as reference values for determining the quality of workmanship – benchmark inspections

- Involvement in performance tests on the facade on the building site (water impermeability, sound insulation, blower door test, etc.)

- Random inspection of the installation work on the building site

- Regular reporting on the installation work including the identification of discrepancies with the original planning

Specials

Buildings, their functions and methods of construction and their technical systems are becoming increasingly complex. Standardised calculation methods are often no longer adequate to determine building physics values. Here Priedemann relies on various computer-based simulation tools. We feed our simulation programs with the planned overall concept consisting of building services, the building structure and the facades and climate data in order to determine the achievable comfort values according to ISO 7730 or the heating and cooling loads.

The absolute, relative (perceived) and maximum room air temperature or the maximum number of hours in which these values are exceeded are often the main factors.

To this end, particularly critical rooms in a building are identified and analysed so that recommendations can be made for further specific planning. When we need to analyze particularly complex systems or processes, we use a range of 3-dimensional flow simulations (CFD Computational Fluid Dynamics). For this purpose, we convert the given three-dimensional building structure into CFD-readable data sets and enter the energetic, building physics and weather data into the program. For example, statements on flow velocities, temperature distributions in the room air and on surfaces can be determined.

We also use CFD programs for the verification of smoke extraction scenarios as well as necessary or planned smoke extraction and post-flow cross-sections. Cross-sections or the number of conventionally determined smoke extraction openings can thus be optimised and often reduced.

The facade is the “face” of a building,a surface and a medium, which the building uses to communicate with its surroundings. The arrangement of open and closed surfaces, the materials used – all this reveals something about the interior life of a building and how it relates to its surroundings.

However, the metaphor of the “medium” can also be translated directly onto the facade by turning it into a “media facade”. Depending on the sharpness of detail and type of message, as well as the viewing distance, the facade surfaces differ in the size and number of pixels required. One of these pixels may be the size of a light-emitting diode or take up an entire facade or window element, depending on whether graphic animations, lifelike images, video sequences or texts are to be shown.

Priedemann plans all types of media facades and integrates them into the overall design. It is our aim that the media facade is part of the whole, including operation and maintenance, and is not reduced to the level of an appendage or a technical gimmick. For example, we develop concepts in which the energy needed to operate is generated by the facade itself. We take care of the necessary planning and performance data and create a feasible facade design. In the Facade-Lab area we develop transparent media facades together with industrial partners from the glass industry.

Memberships

© 2025 Priedemann