GKD

Material Data

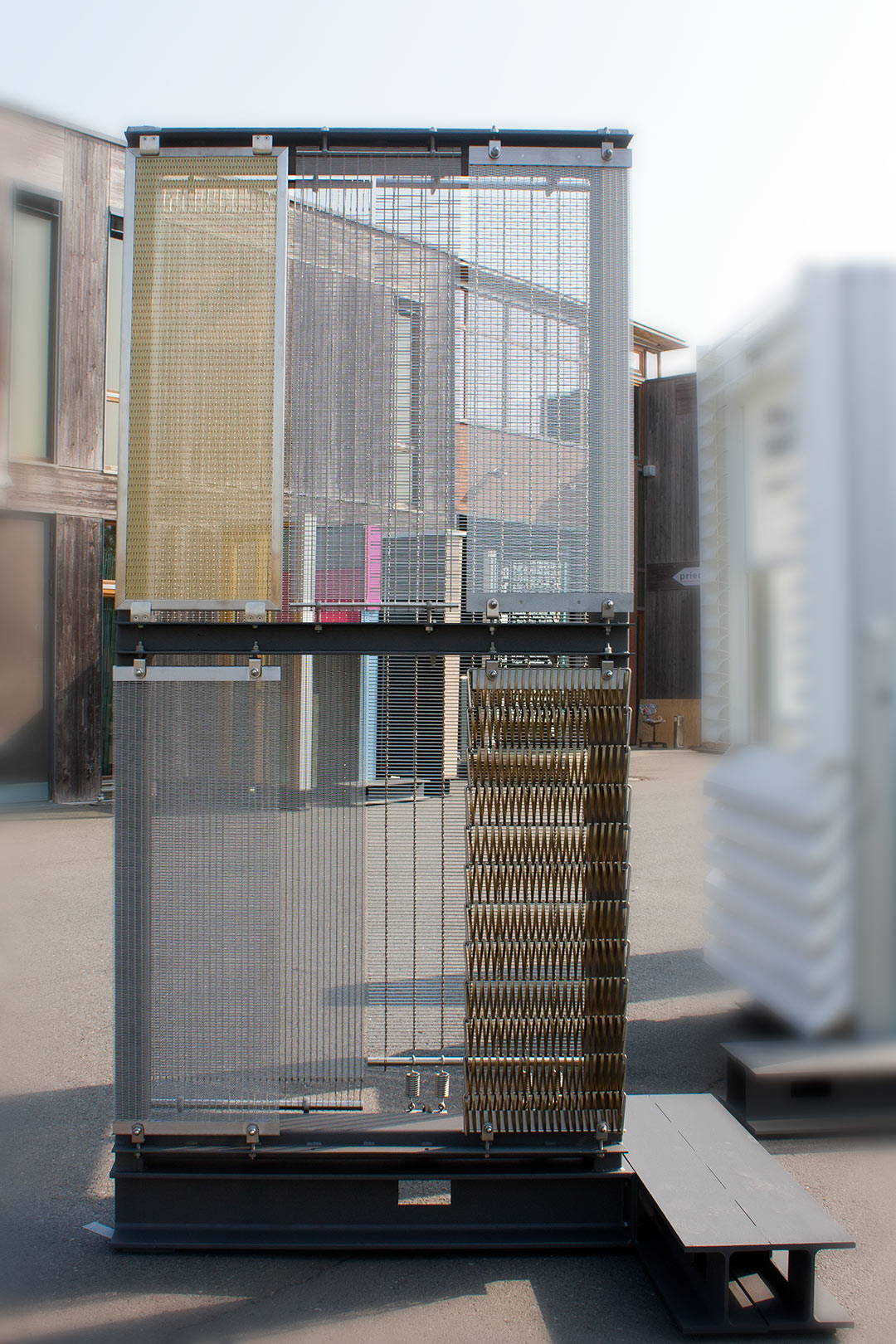

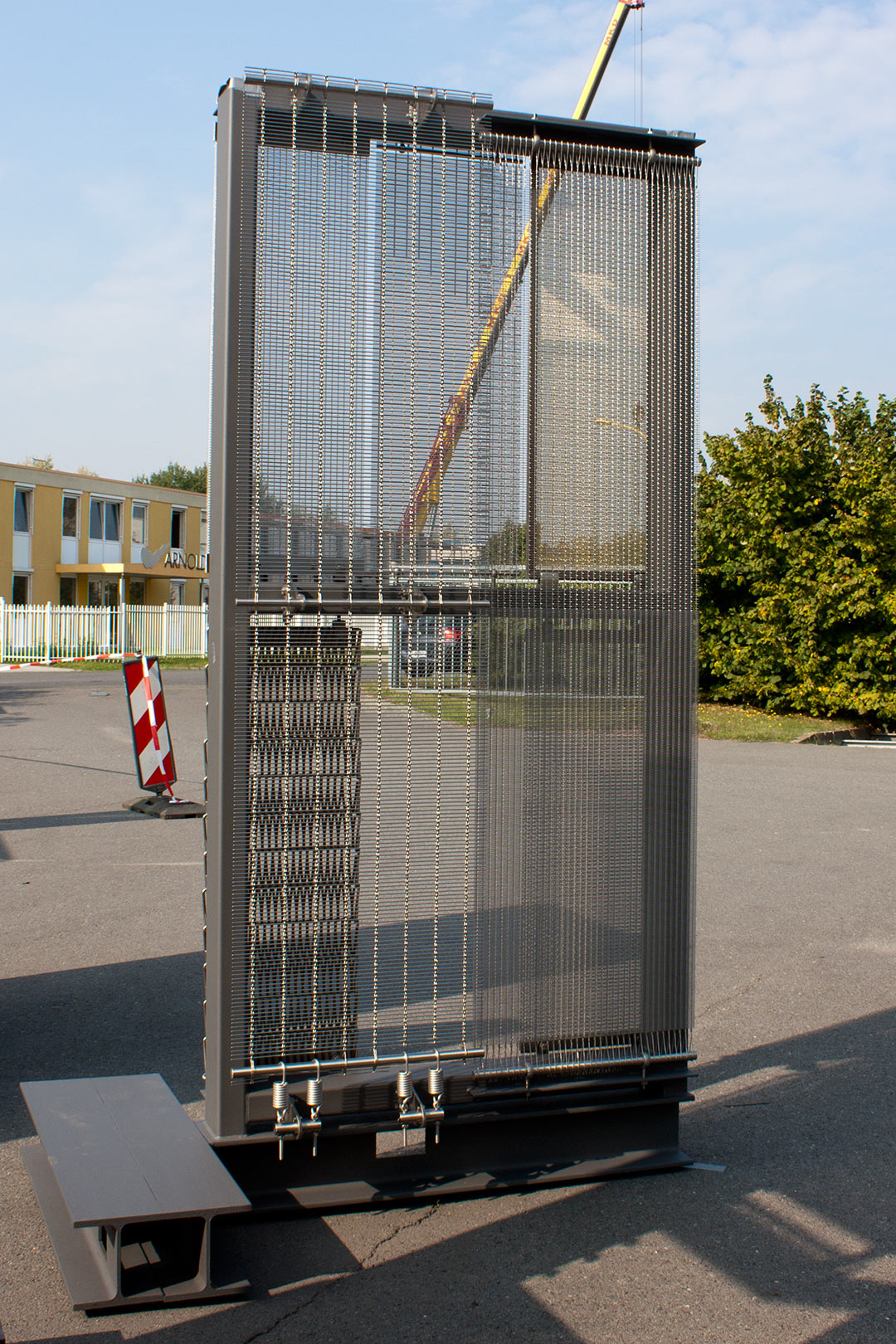

Front elevation

Metal mesh for architecture and design

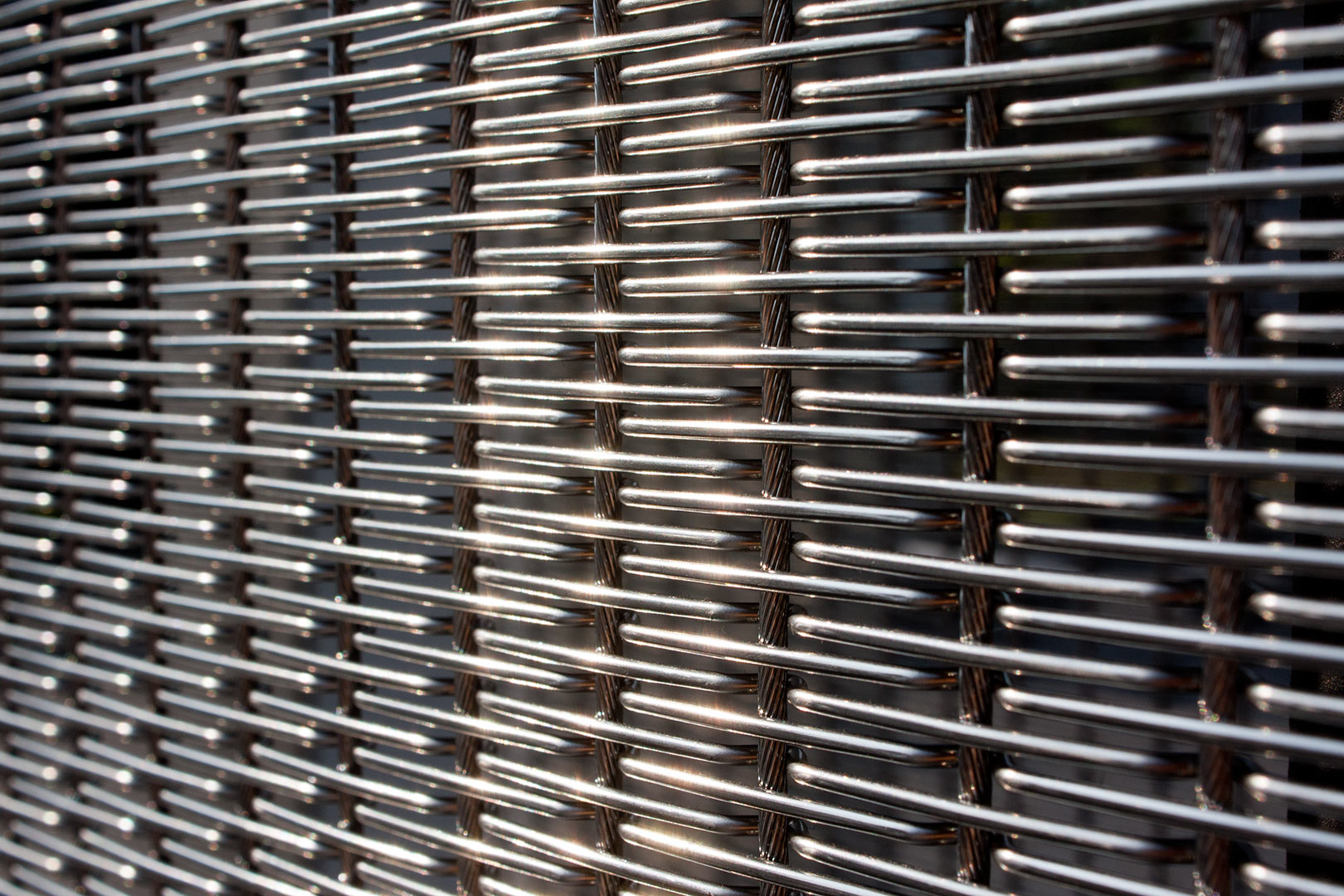

- Design Tigris, stainless steel, woven rod mesh,including plates and springs, open area of 62.1 %, total thickness approx. 6.2 mm, weight 6 kg/m², round bar at the top/ bottom d= 26 mm, in the middle 20 mm

- Design Omega 1550, stainless steel, cable pressed to loop, open area 65 %, weight approx. 3.32 kg/m², max. width 7.92 m

- Design Omega 1510, stainless steel, cable pressed to loop, open area 35 %, total thickness approx. 4.5 mm, weight 6.65 kg/m²

Rear elevation

Metal mesh panel

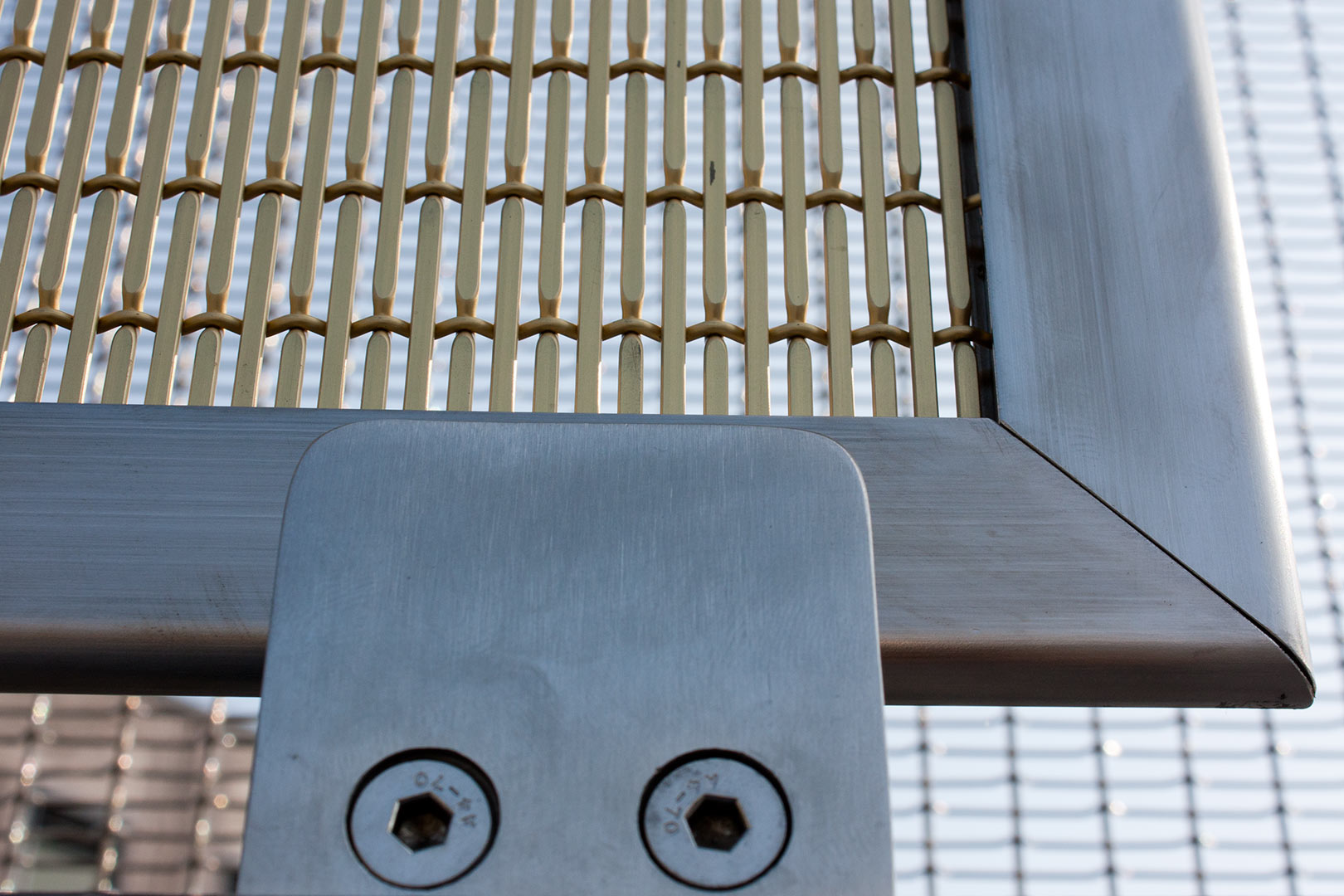

- Design ALU 6010, aluminum, gold-colored anodized with fusiomesh and clevis screws, open area 45.7 %, total thickness approx. 3 mm, weight 2.5 kg/m²

- Design Lago, stainless steel, with inserted round bar, d = 12 mm and eye- bolts, open area 44 %, total thickness approx. 3.5 mm, weight 6.8 kg/m²

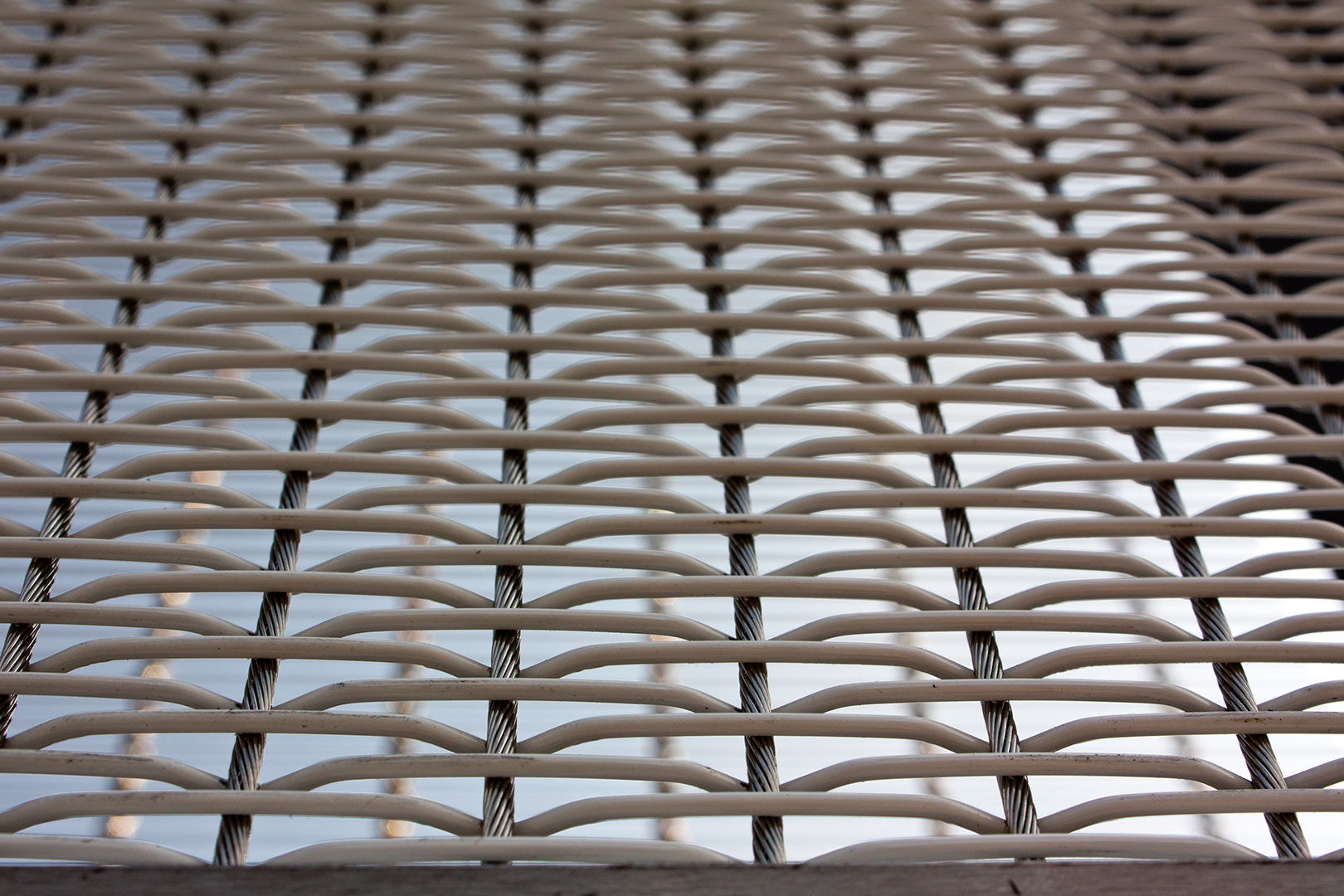

- Design Omega 1520, stainless steel, rod coated white, with Fusiomesh and clevis screw, open area 50.6 %, thickness total ca. 4.5 mm, weight 5.2 kg/m²

- Design PC-Omega 1520, with tensioning joint and clevis screws, open area 51 %, total thickness approx. 5 mm, weight 6.1 kg/m²

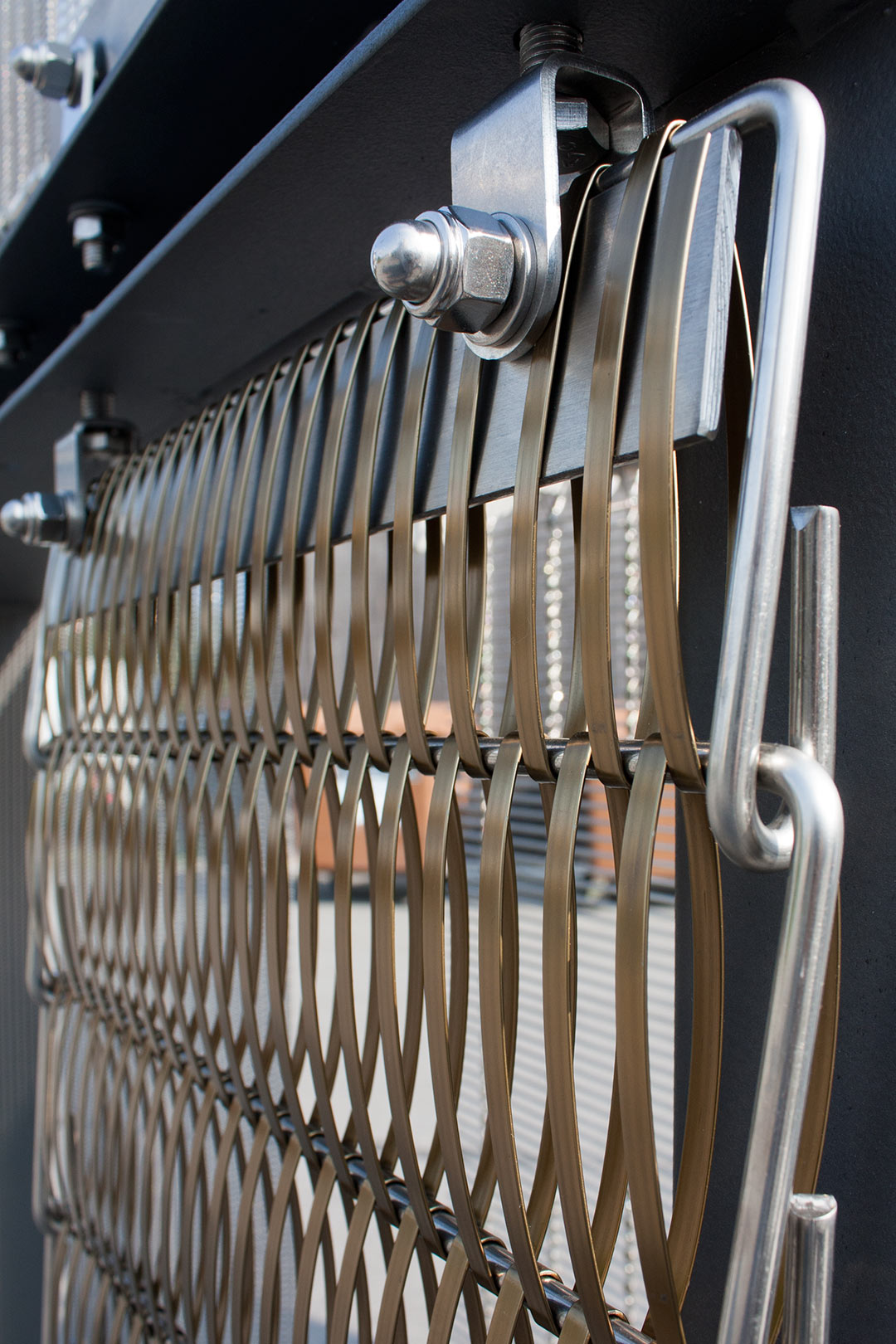

- Design Escale 5×1, stainless steel with inserted flat 40 × 4 mm and clevis screw, open area 33 %, thickness total ca. 10.5 mm, weight 9.3 kg/m²

- Design Escale 7×1, stainless steel, spiral coated gold colored, with inserted flat 50×6 and clevis screw, open area 36 %, total thickness approx. 22 mm, weight 8.9 kg/m²

Fixing

Variable, according to requests, such as framed mesh panel fixing with angle and flat steels, attachment for mesh-panels with weft rods, fixing with eyebolts, clamping profiles

Characteristics

Semi-transparent media facade – LEDs integrated in stainless steel mesh, high durability, max. mesh width according to requirement

7

7 8

8