Tiger Coating

Material Data

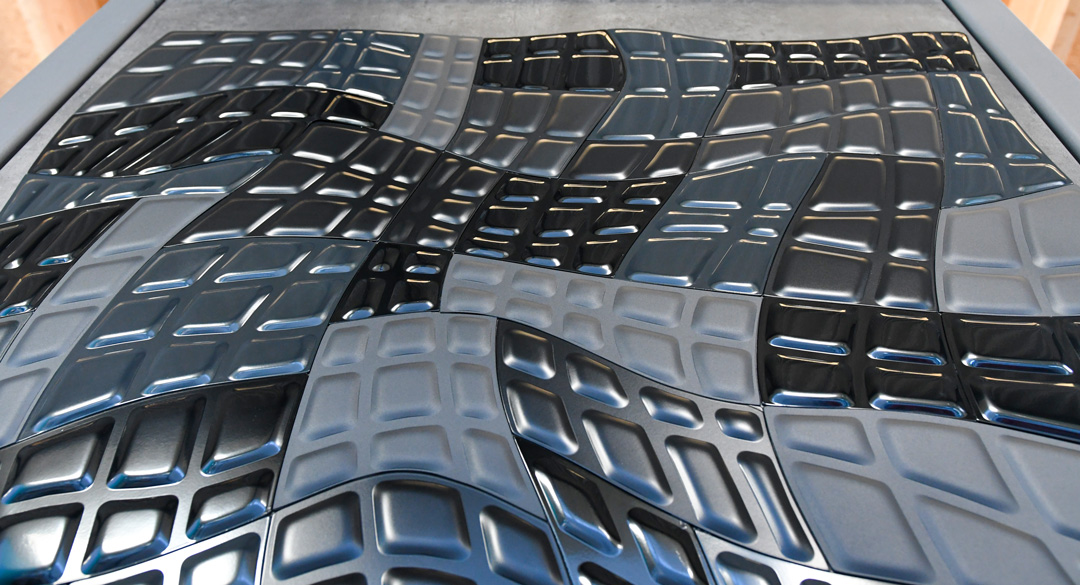

Front elevation

3D aluminium panel, lasered into parts, then “powdered” and reassembled, various degrees of gloss!

- AL 7021 – TIGER Drylac® 14/70065,

smooth/ semi gloss, degree of gloss 70 ± 5,

GSB Standard/ Qualicoat Class I - RAL 7021 – TIGER Drylac® 29/71263, fine structure, matte, GSB Standard/ Qualicoat Class I

- 54 B – TIGER Drylac® 68/80145,

smooth/ matte, degree of gloss 25 ± 5,

GSB Master/ Qualicaot Class II - RAL 9005 – TIGER Drylac® 68/80032,

smooth/ matte, degree of gloss ca. 25 ± 5,

GSB Master/ Qualicoat Class II - RAL 9005 – TIGER Drylac® 29/80020,

smooth/ glossy, degree of gloss ca.80-95,

GSB Standard/Qualicoat Class I

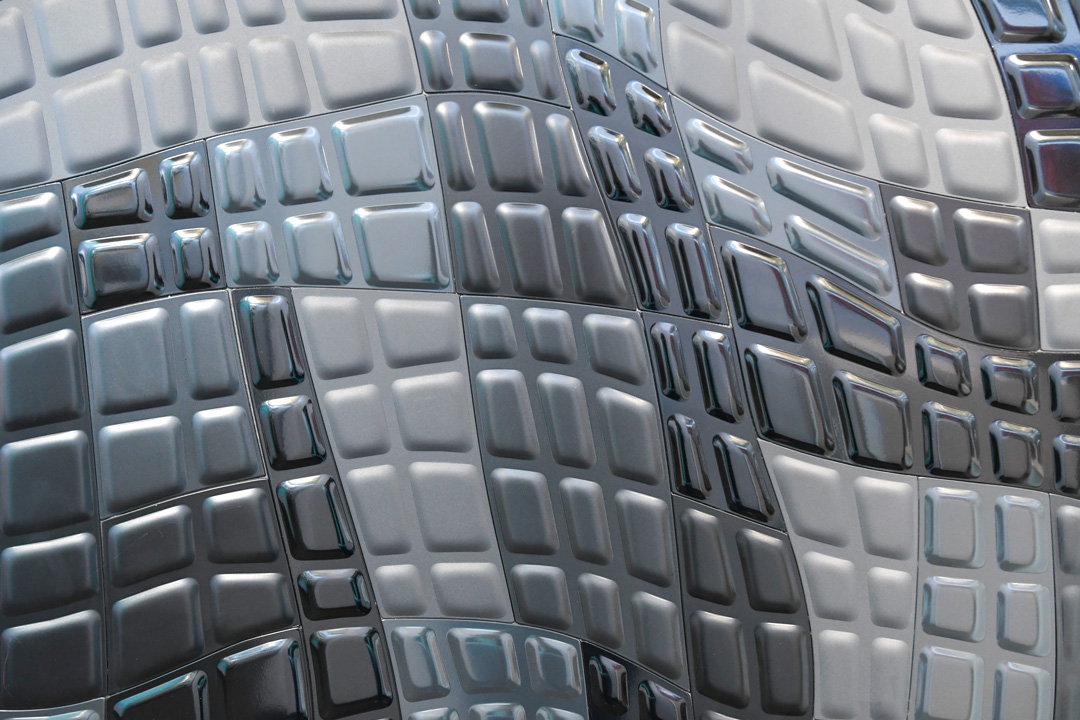

Rear elevation

Hinged 3D sheet metal panels powder coated with “Superdurable facade Powder” by TIGER

- TIGER Drylac® 68/90015, sun gold metallic,

smooth/ matte, “Superdurable”,

GSB Master/ Qualicoat Class II - TIGER Drylac® 68/90091, copper metallic,

smooth/ semi gloss, “Superdurable”,

GSB Master/ Qualicoat Class II - TIGER Drylac® 58/90117, copper metallic,

smooth/ semi gloss, “Superdurable”,

GSB Master/ Qualicoat Class II, AAMA 2604 - TIGER Drylac® 68/60116, rosty matte,

metallic fine texture,“Superdurable”,

GSB Master/ Qualicoat Class II - TIGER Drylac® 68/60112, RAL 017,

fine tecture/ matte, “Superdurable”,

GSB Master/ Qualicoat Class II - TIGER Drylac® 68/60115, rosty iron,

metallic fine texture, “Superdurable”,

GSB Master/ Qualicoat Class II

Characteristics

Highly weather resistant powder coatings, fine textured surface effects

7

7 8

8 9

9