Architectural Competitions

Refurbishment

Feasibility Study

Project/Peer Review

Project Objectives and Brief

Concept/Schematic Design

Detailed/Developed Design

Technical/Construction Design

Specification/Tender Documentation

Tender Evaluation

Design Compliance Control

Mock-Up Association

Execution Compliance Control

Handover, As-Built Documentation

Variation Claim Evaluation

Monitoring

Defect and Failure Investigation / Expert assessments

deen

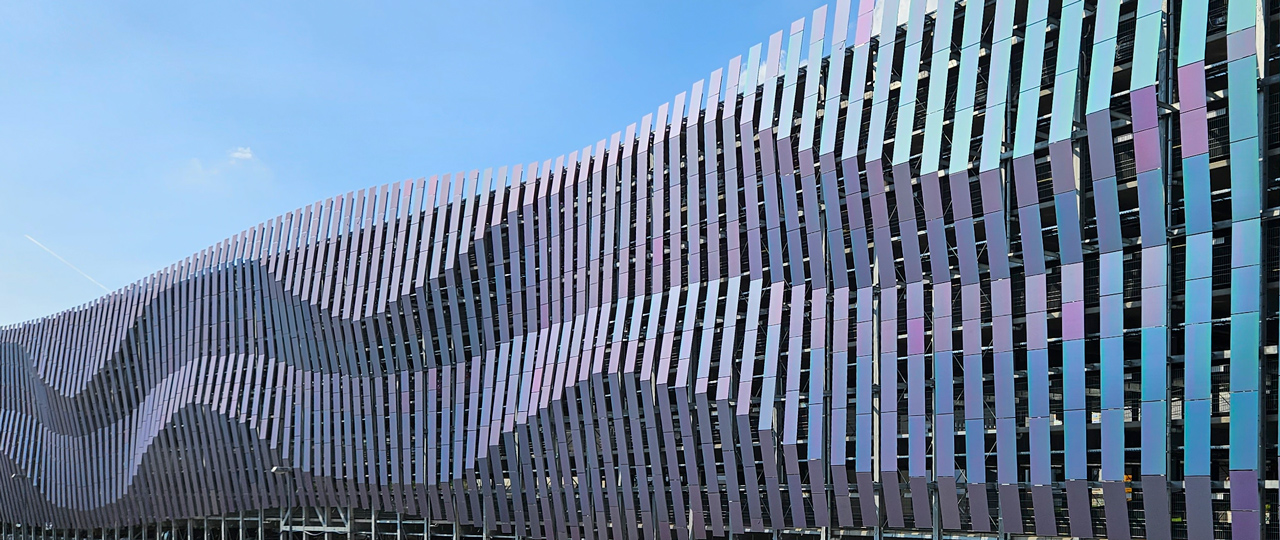

DHL-Campus, Schkeuditz

Rubin 65 GmbH

Owner / Developer

Stadtbau Leipzig AG

Architect

Architektur von Domaros GmbH

Building Function

Car park, Office

Status

Under construction

approx. 2.200 m²

Height

approx. 17 m

Technical Features

- Facade perceives a spatially-acting wave

- PV modules supported by a 15 m high, up to 2 m cantilever steel substructure in 200 different sections

- The colour effect of the PV modules varies based on sunlight exposure and the observer’s viewing angle

We provided

Consultancy

Priedemann sees the implementation planning as a precise simulation of the construction process and the building – in detail, digitally and, depending on the complexity, as a 3-dimensional model.

- Guide-detail planning as CAD drawing on a scale of 1:1 with all connections to adjacent components

- Detailed representation of the layers, components and individual components of the facade solution supplemented by material descriptions and dimensioning

- Planning on the basis of static pre-dimensioning for the relevant facade components – glass, profiles, fixings

- Advanced planning for the building physics and acoustics

- The specified security and fire safety requirements are taken into consideration

- Planning and integration of control and operating components

- Updating costs and the construction schedule

- Agreed plan for the materials

- Glass specifications

The supervision of assembly and installation is particularly important for us, to ensure the agreed quality. Our principle is that deviations from the agreed planning must be identified at an early stage, documented and the implementation corrected. This controlling refers both to production and manufacturing as well as to the assembly on the building site:

Regular inspection of production and assembly in the factory- Verification of compliance with the approved design, ensuring compliance with the agreed qualities, standards and test series

- Regular reporting on production progress; the reports contain recommendations for possible improvements as well as a list of unfulfilled services, performance arrears, defects identified

- Verification of compliance with the approved design, ensuring compliance with the agreed qualities, standards and test series

- Inspection of examples of facade sections as reference values for determining the quality of workmanship – benchmark inspections

- Involvement in performance tests on the facade on the building site (water impermeability, sound insulation, blower door test, etc.)

- Random inspection of the installation work on the building site

- Regular reporting on the installation work including the identification of discrepancies with the original planning

Engineering

Priedemann stands for system and facade concepts that think ahead with detailed solutions and technical feasibility even before the contract is awarded, always keeping an eye on the project as a whole and maintaining the project’s design standards even after the contract has been awarded.

- Development of the constructional facade concept on the basis of an integrated procedure together with the developer’s design team

- Development of a technical plan for all of the different facade areas, types and elements

- Project-specific adaptation of existing facade systems, creation of bespoke project solutions

- Design of all typical details as the basis of the structural design plan

- Optimization of production, manufacturing and assembly for the best possible cost-benefit ratio

Specials

Saving fossil fuel, reducing operating costs, increasing efficiency.Around a third of the world’s primary energy is used to operate buildings. Fossil, non-renewable fuels are used for more than 80 percent of this, while the demand for energy is growing at the same time. Energy is usually generated in large central power plants, and the energy is provided via wasteful supply networks. Decentralized energy generation seems more than logical. In addition to solutions to use energy more efficiently and reduce consumption, renewable energy sources must increasingly be developed. Priedemann considers locally usable solar energy in particular to be one of the most sensible solutions.

- Both heat and electricity can be collected with today’s facade systems.

- With both forms of energy, all types of energy required in a building can now be adequately provided.

- Facade surfaces are often larger than roof surfaces: We can harness the potential of solar energy using suitable systems available on the market.

- While the residential sector mainly needs heating energy, the commercial sector mainly needs cooling energy and industry needs energy for processing.

- The highest demand for cooling occurs, when solar radiation is at its highest. With solar cooling systems we can use this inexhaustible source of energy, save fossil fuels, reduce operating costs and increase efficiency.

- We determine the energy demand, evaluate the potential on the basis of local weather data, the building location and orientation and, together with the specialists involved, develop concepts and solutions for energy generation integrated into the facade.

- Architectural 3D models are often created as surface or node models. We analyze this data and transform it into realistic volume models on the basis of which facade components can later be produced.

- We provide information on details that would pose special challenges during implementation or could not be built, e.g. if tested systems or approved products are not applicable, or connections would be so delicate that they could not absorb the loads.

- So that we can react flexibly to the different system environments, we are equipped with the current programs such as Rhino, Grasshopper, Archicad, Revit, AutoCad, Athena or Solid Works and are familiar with many other programs.

We know that planning is a living process accompanied by change. Parametric data models allow us to react flexibly to changing conditions or situations. Parametric planning can be an integral part of a BIM process or an independent part of planning and implementation. Using different 3D software, we design individual facade components, elements or entire assemblies and use them to generate CIM (computer integrated manufacturing) and DFM (design for manufacture) compatible data sets.

These data sets can be transferred to CNC data (Computer Numeric Control) for production. Parametric planning is an efficient and reliable tool for consistent planning and accuracy, especially for complex facade geometries – from design to manufacture and installation. Our parametric data models provide us with a reliable basis for tendering, awarding and implementation.

Memberships

© 2022 Priedemann