Architectural Competitions

Refurbishment

Feasibility Study

Project/Peer Review

Project Objectives and Brief

Concept/Schematic Design

Detailed/Developed Design

Technical/Construction Design

Specification/Tender Documentation

Tender Evaluation

Design Compliance Control

Mock-Up Association

Execution Compliance Control

Handover, As-Built Documentation

Variation Claim Evaluation

Monitoring

Defect and Failure Investigation / Expert assessments

deen

KPMG HQ, Berlin

INVESTA, HOCHTIEF and Groth Group

Owner / Developer

Köbis Dreieck Berlin-Fonds GmbH & Co. KG

Architect

- Nicolas Grimshaw &Partners, London

- Claus Neumann Architekten, Berlin

Building Function

Office

Status

Completed 10/2005

approx. 12.200 m²

Height

approx. 27 m

Technical Features

- Unitized curtain wall, integrated maintenance walkway

- External sunshade, controlled vertical glass lamellas

- Stick system facade

- Parallel opening windows, integrated sunscreen

- Atrium skylight

We provided

Consultancy

At Priedemann any project starts with the determination of the planning basis, with the facts, requirements and possibilities – no matter when we start and always together with everyone involved in the project

- What is the design concept?

- Which local standards apply?

- Urban planning requirements?

- Energy requirements?

- Weighing up the priorities in the “magic triangle” of quality, costs and duration

- Definition of an objective as a benchmark for all subsequent planning phases

- Development of the evaluation criteria as expert assessors in architectural competitions

Priedemann develops the facade concept for planning ready for approval – taking into account all planning principles and requirements determined up to that point, e.g. the climate plan, building technology and building statics.

- Detailed hand-drawn sketches

- CAD-based layout plans and CAD-guided details

- 3-dimensional analysis of the shell of the building for complex facades

- Selection of the materials and type of facade

- Drafting of the facade plan on the basis of the building physics and acoustic specifications

- Integration of fire safety and smoke extraction plans

- Security requirements are taken into consideration

- Collaboration on the overall design so that it can be approved

- Joint design, joint width and depth in accordance with the building movements identified and relevant tolerances

- Documentation in report form

- Ongoing updating and further development of the design, cost estimate and construction scheduling

- Support in the planning and implementation of 1:1 facade samples to ensure that the design is progressing as intended, e.g. in design-and-build processes

Priedemann sees the implementation planning as a precise simulation of the construction process and the building – in detail, digitally and, depending on the complexity, as a 3-dimensional model.

- Guide-detail planning as CAD drawing on a scale of 1:1 with all connections to adjacent components

- Detailed representation of the layers, components and individual components of the facade solution supplemented by material descriptions and dimensioning

- Planning on the basis of static pre-dimensioning for the relevant facade components – glass, profiles, fixings

- Advanced planning for the building physics and acoustics

- The specified security and fire safety requirements are taken into consideration

- Planning and integration of control and operating components

- Updating costs and the construction schedule

- Agreed plan for the materials

- Glass specifications

For tendering and awarding contracts Priedemann defines and specifies the planned facades and details as well as the connections to adjacent components.

- Summary of technical requirements as well as client and user specifications for construction and materials as “Technical Preliminary Remarks”.

- Compilation of the design and additional technical criteria in coordination with the planning team

- Drafting of the service description

- Individual quantities and components are recorded

- Differentiation of the various trades when awarding contracts to different contractors, clear definition of the interfaces

- Collation of all documents in a single set of documentation

Priedemann provides clients with comprehensive advice independent of individual manufacturers and systems when selecting the best award procedure and the most suitable manufacturer.

- Comparison and evaluation of the tenders that have been submitted

- Creation of price comparison lists

- Evaluation of alternative providers

- Evaluation of the qualification certificates of the facade manufacturers

- Assessing the capabilities and capacities of potential contractors

- Involvement in the discussion when contracts are awarded

We know the market: Our experience from hundreds of projects with various manufacturers is incorporated into our consulting services.

The first phase after the award of the contract is of particular importance. Often some time has passed since planning and a number of changes may have occurred, the planning team has changed, user requests have been added or additional requirements are putting pressure on the budget. Priedemann checks and assesses whether all of the documents are up to date, complete, feasible and if any improvements can be made, coordinates change management and is the contact for all questions of the planning team concerning the facade.

Before the work is planned- Checking that the documents provided are complete

- Comparison with possible project changes and updates

- Determining the status quo for the start of construction

- Checking the system components to be implemented

- Clarification of unresolved questions, communication with the planning team

- Priedemann checks and comments on the contractor’s structural assumptions as well as the performance in terms of energy and acoustics

- Checking and evaluating the contractor’s work schedule

- Checking relevant facade elements and how they interface with other trades

- Evaluation of the contractor’s planning and system design

- Checking of technical specifications for materials such as glass, stone etc. as well as data sheets for sealing and insulating materials, surfaces, system descriptions etc.

- Checking and assessing the facade supply chain for compliance with the applicable guidelines as well as technical and quality standards

- Comparison of test data with specified or actual performance data

- Updating change management

- Investigation of options for production, materials and technology, if necessary making improvements whilst retaining the agreed qualities, costs and dates for implementation

- Evaluation of facade materials that the facade manufacturer provides as an IFC (issued for construction) alternative

- Statement on the suitability, quality and equivalence of alternative material proposals in relation to the materials in the original plans

- Assessment and evaluation of the behavior of the products when processed

Scale does not just changes the perspective and the proportions, only in the 1:1 model can the loads a component is exposed to be tested realistically.

Usually, mock-ups are only created after being awarded to the manufacturer of a facade. We support the planning and implementation already during the planning phase in order to ensure greater reliability of planning, design and implementation at an earlier point in time.

- Support and advice when carrying out facade tests

- Control of the standards and requirements to be met, involvement in tests

- Evaluating and commenting on the test reports

- Recommendations for potential improvements

- Support and advice on the construction of a facade sample to match the design requirements

The supervision of assembly and installation is particularly important for us, to ensure the agreed quality. Our principle is that deviations from the agreed planning must be identified at an early stage, documented and the implementation corrected. This controlling refers both to production and manufacturing as well as to the assembly on the building site:

Regular inspection of production and assembly in the factory- Verification of compliance with the approved design, ensuring compliance with the agreed qualities, standards and test series

- Regular reporting on production progress; the reports contain recommendations for possible improvements as well as a list of unfulfilled services, performance arrears, defects identified

- Verification of compliance with the approved design, ensuring compliance with the agreed qualities, standards and test series

- Inspection of examples of facade sections as reference values for determining the quality of workmanship – benchmark inspections

- Involvement in performance tests on the facade on the building site (water impermeability, sound insulation, blower door test, etc.)

- Random inspection of the installation work on the building site

- Regular reporting on the installation work including the identification of discrepancies with the original planning

Specials

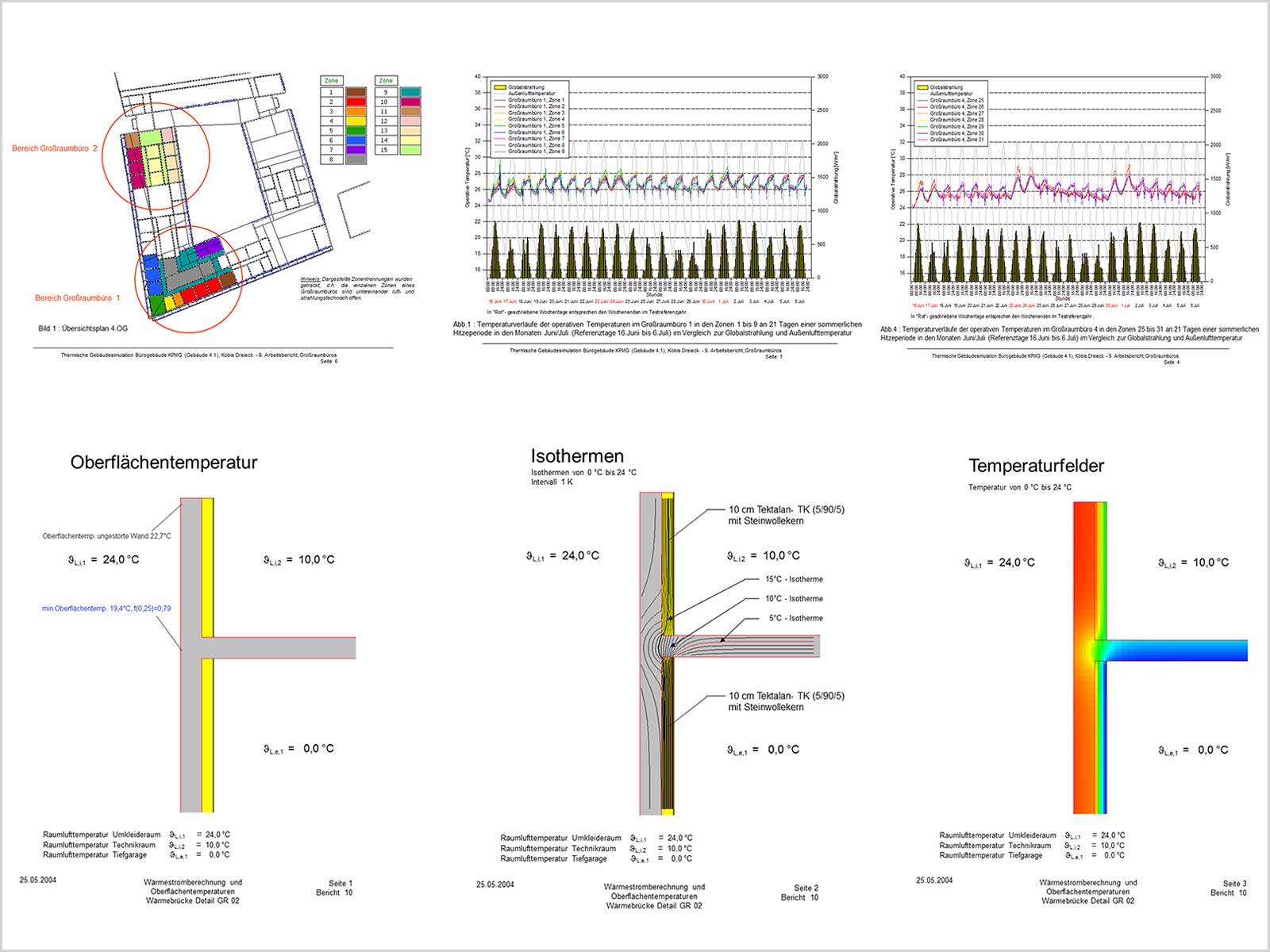

The aim of Priedemann’s thermal-structural planning is to minimise heat losses and undesirable heat input through the exterior of the building and to avoid damage caused by weather conditions. The range of services includes identifying all influences and values relevant for the facade structure as well as the exact dimensioning and determination of the materials for the layer structure of the facade.

- Thermal insulation: On the basis of local and specific project requirements and after evaluation of the technical building plan, we determine the necessary values for thermal insulation in the summer and winter.

- Energy standards: We take into account which energy standards and objectives must be met – such as KfW requirements, low and passive house standards or requirements of green building labels such as LEED, BREAM or DGNB.

- Materiality: We calculate the necessary U-values and resulting insulation thicknesses, make specific material suggestions, give advice on the correct wall structure and determine the g-values taking into account the measures selected to provide protection from the sun.

- Overall energy performance: We determine the necessary values from building services and the facade to work out the overall energy performance of the building. An important component, especially in residential buildings, is the calculation of the transmission heat loss of the entire exterior of the building.

- Isothermal profile and thermal bridges: We analyse the isothermal profile within the planned or implemented construction, calculate 2 or 3 dimensional thermal bridges and give recommendations to avoid condensation forming

- Component construction with layer construction: Depending on the commission, we draw up a catalogue for the entire building or selected components, which shows the scale of each individual component in its layer structure and specifies the material qualities in order to give those involved in planning certainty about the structural-physical qualities of the planned construction.

- Advice throughout every phase: This is the basis on which we advise architects and builders, general contractors and facade manufacturers, whom we assist in all planning and implementation phases.

Priedemann produces energy saving certificates based on the existing building data, which represent the most important energy consumption data and characteristic values in accordance with local legal requirements. For Germany we are also authorized to assess such evidence.

For completed projects or ongoing projects – depending on local regulations and the determination of specific building data – we can issue energy efficiency certificates that illustrate the energy consumption of the building as a whole, i.e. in the interaction of building services, facade and use.

Memberships

© 2022 Priedemann