Architectural Competitions

Refurbishment

Feasibility Study

Project/Peer Review

Project Objectives and Brief

Concept/Schematic Design

Detailed/Developed Design

Technical/Construction Design

Specification/Tender Documentation

Tender Evaluation

Design Compliance Control

Mock-Up Association

Execution Compliance Control

Handover, As-Built Documentation

Variation Claim Evaluation

Monitoring

Defect and Failure Investigation / Expert assessments

deen

NPP Control Tower, Doha

Arab Engineering Bureau

Owner / Developer

Port Authority, State of Qatar

Architect

PLP Architecture

Building Function

Mixed-Use, Office, Port Navigation

Status

Completed 03/2017

approx. 26.000 m²

Height

approx. 110 m

Technical Features

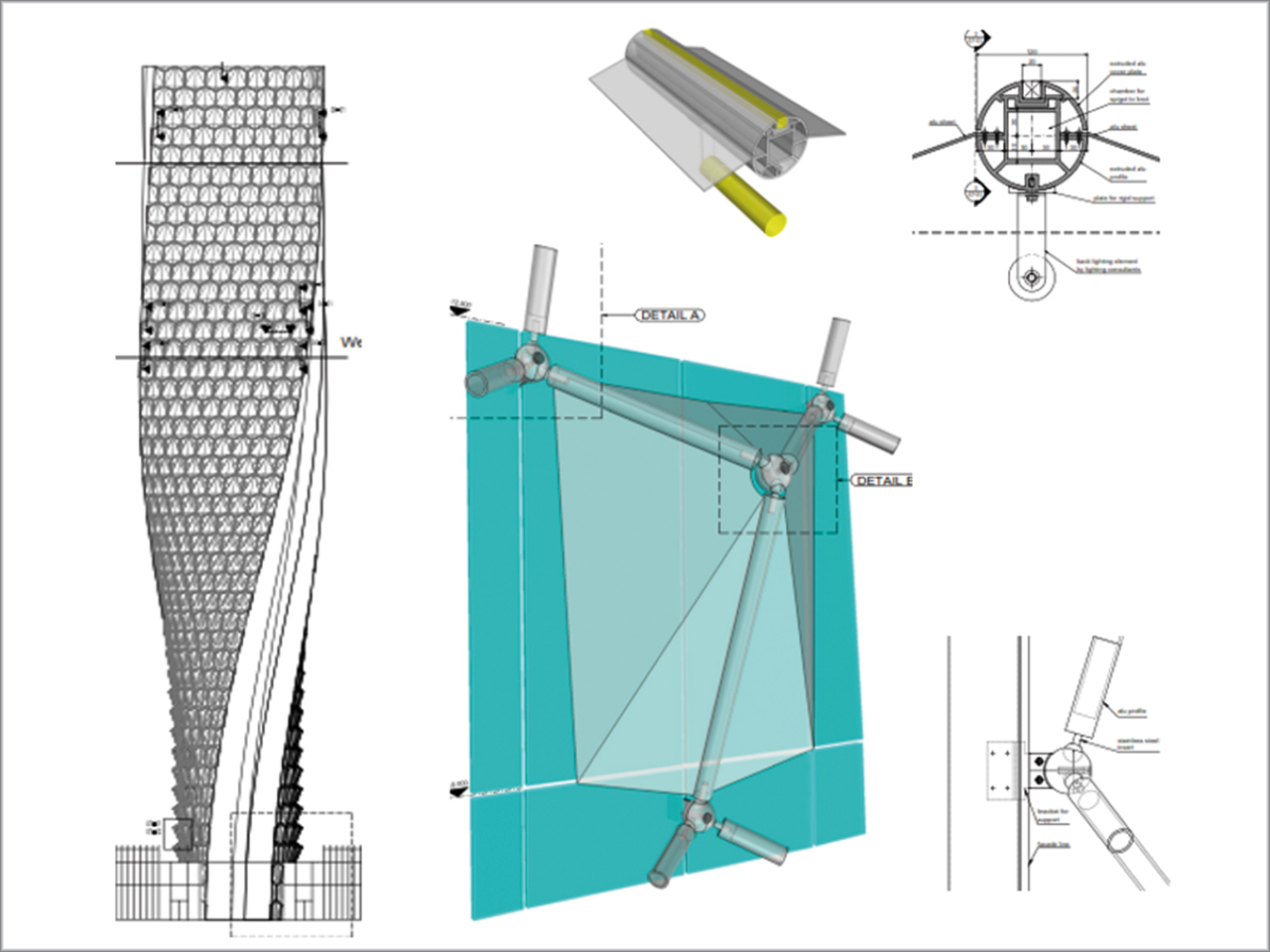

- Twisted facade

- Unitized curtain walls, cold-bent glass

- Stick system, structural glazing, glass fins

- Sunshade elements

We provided

Consultancy

At Priedemann any project starts with the determination of the planning basis, with the facts, requirements and possibilities – no matter when we start and always together with everyone involved in the project

- What is the design concept?

- Which local standards apply?

- Urban planning requirements?

- Energy requirements?

- Weighing up the priorities in the “magic triangle” of quality, costs and duration

- Definition of an objective as a benchmark for all subsequent planning phases

- Development of the evaluation criteria as expert assessors in architectural competitions

We design different variants based on the strategic objectives, we identify their advantages and disadvantages and keep on developing the preferred solution.

- Sketches of concepts drawn by hand

- Taking into account different options for materials and the construction

- Inclusion of structural and thermal loads

- Dependencies in the building structure are taken into consideration

- The physics of the building and acoustic requirements are taken into consideration

- Fire protection and smoke extraction are taken into consideration,

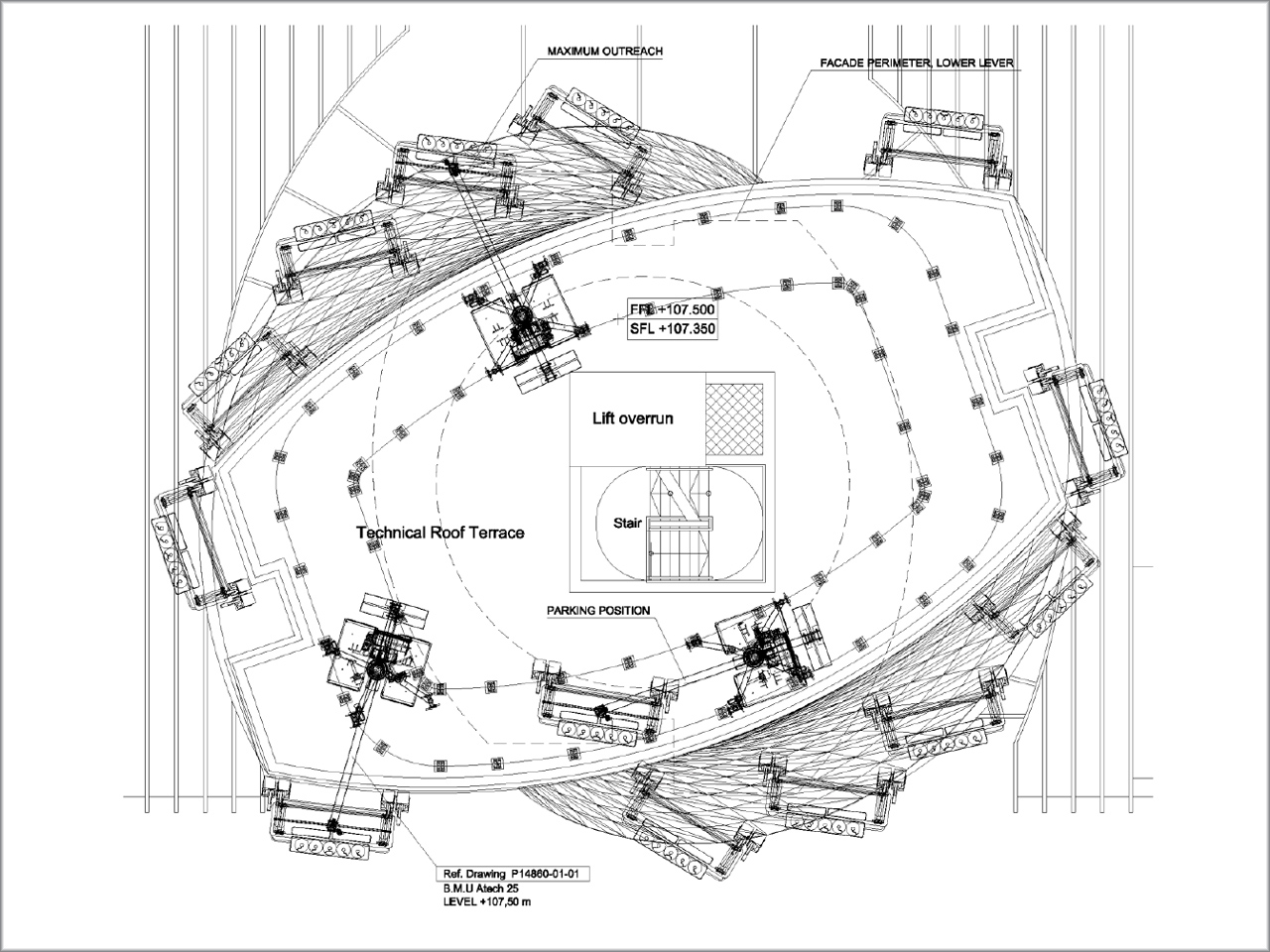

- Cleaning and maintenance plan, access at heights

- Outlining solutions, costs and timings

- Inclusion of existing solutions to clarify the design

- Support during the initial sampling

- Documentation in report form

- Ongoing updating or further development of the design

Priedemann develops the facade concept for planning ready for approval – taking into account all planning principles and requirements determined up to that point, e.g. the climate plan, building technology and building statics.

- Detailed hand-drawn sketches

- CAD-based layout plans and CAD-guided details

- 3-dimensional analysis of the shell of the building for complex facades

- Selection of the materials and type of facade

- Drafting of the facade plan on the basis of the building physics and acoustic specifications

- Integration of fire safety and smoke extraction plans

- Security requirements are taken into consideration

- Collaboration on the overall design so that it can be approved

- Joint design, joint width and depth in accordance with the building movements identified and relevant tolerances

- Documentation in report form

- Ongoing updating and further development of the design, cost estimate and construction scheduling

- Support in the planning and implementation of 1:1 facade samples to ensure that the design is progressing as intended, e.g. in design-and-build processes

Priedemann sees the implementation planning as a precise simulation of the construction process and the building – in detail, digitally and, depending on the complexity, as a 3-dimensional model.

- Guide-detail planning as CAD drawing on a scale of 1:1 with all connections to adjacent components

- Detailed representation of the layers, components and individual components of the facade solution supplemented by material descriptions and dimensioning

- Planning on the basis of static pre-dimensioning for the relevant facade components – glass, profiles, fixings

- Advanced planning for the building physics and acoustics

- The specified security and fire safety requirements are taken into consideration

- Planning and integration of control and operating components

- Updating costs and the construction schedule

- Agreed plan for the materials

- Glass specifications

For tendering and awarding contracts Priedemann defines and specifies the planned facades and details as well as the connections to adjacent components.

- Summary of technical requirements as well as client and user specifications for construction and materials as “Technical Preliminary Remarks”.

- Compilation of the design and additional technical criteria in coordination with the planning team

- Drafting of the service description

- Individual quantities and components are recorded

- Differentiation of the various trades when awarding contracts to different contractors, clear definition of the interfaces

- Collation of all documents in a single set of documentation

As an independent expert, Priedemann examines the implementation of a facade concept or project with regard to how easy it is to build and its feasibility as well as the associated costs and risks.

- Evaluation of the impact of a facade design on the cost and time frame of the project

- Assessment of the resources and capacities selected with regard to completion to deadline

- Investigation of the suitability of a selected system for the desired project objective

- Identification of possible contradictions between agreed project goals, existing knowledge and given standards

Engineering

With the award of the contract, we check the contractual framework conditions as the basis for the implementation. If necessary, we adapt the technical solutions to any requirements that have changed – always with the goals of our client in mind.

- Contract review, determination of the contracted services and if necessary, developing alternative solutions

- Operational management, cost and budget audits

- Assessment of technical amendment suggested by the contracting parties, assessment of proposed modifications

- Evaluation of implementation alternatives to the approved diagrams (IFC Issued for Construction Drawings)

- Definition of the main strategic objectives as the basis for a coordinated facade design

Priedemann stands for system and facade concepts that think ahead with detailed solutions and technical feasibility even before the contract is awarded, always keeping an eye on the project as a whole and maintaining the project’s design standards even after the contract has been awarded.

- Development of the constructional facade concept on the basis of an integrated procedure together with the developer’s design team

- Development of a technical plan for all of the different facade areas, types and elements

- Project-specific adaptation of existing facade systems, creation of bespoke project solutions

- Design of all typical details as the basis of the structural design plan

- Optimization of production, manufacturing and assembly for the best possible cost-benefit ratio

Depending on requirements, Priedemann analyzes and calculates the static requirements of e.g. profiles, glazing and fixings in 2 or 3 dimensions or as finite elements. Evidence is provided on the basis of the applicable international or national standards.

- 2D construction analysis and detailed 3D analysis as needed

- Profile and glass structural specifications

- Calculation and analysis of finite elements

- Project structural analysis as documentation for the relevant auditors

- Structural evidence depending on the region based on EN standards or Eurocode, British Standards or American Standards.

Climate, wind and weather – the reality for a design is always tougher than the theory. Especially with innovations and customer-specific solutions, material and performance tests under real conditions are indispensable. The development of mock-ups and the coordination and monitoring of numerous load tests are central components of our services.

Architectural, visual mock-up (VMU):

Consultation with the developer for the design of a sample facade, on site or on Priedemann’s own premises, preparation of technical drawings and specifications, product and material research, preparation and compilation of factory and assembly drawings (assembly drawings, installation drawings), advice when selecting the most suitable manufacturer, coordination where adaptations are required

Test facade, performance mock-up (PMU):

Consultation with the developer for the design of a sample facade and the necessary test requirements, preparation of technical drawings and specifications, product and material research, preparation and compilation of factory and assembly drawings (assembly drawings, installation drawings), advice when selecting the most suitable manufacturer

On site facade test:

Consultation with the developer on on-site tests on the final elements or those actually installed, blower door test (test for airtightness), site camber test (on-site load test of a defined section of the realized facade or facade mock-up for air and water permeability and structural loads)

If Priedemann takes over the shop drawings or the workshop planning for the contractor of a facade project, we first check the existing planning approval for completeness and feasibility. In discussion with the developer and his planning team, we coordinate all planning-relevant parameters and adapt them, if necessary, to the equipment of the contractor – our client.

- Assessment of the planning approval (IFC Drawings) for completeness and feasibility

- Optimization of the design and assembly plan according to the needs of our client

- Clarification of the division of responsibilities and planning-relevant parameters in coordination with the developer and client

- Drafting of the workshop plans (Shop Drawings)

- Our planning includes the construction in all sections as well as the identification of all materials, qualities, fittings and surfaces

- Review and adaptation of drawings during the approval phase

In addition to careful planning, the quality of the products and materials used is decisive for how well a facade performs and how long it lasts. Our knowledge is guaranteed and supported by our experience and application-oriented research in the Facade Lab. The exact definition of the materials to be used, their quality criteria and how they should be processed is part of our range of services.

- Preparation of the orders for all necessary materials

- Checking the technical data submitted for the materials

- Comparison of the materials proposed by the contractor with the specified materials

- Development of project-specific quality criteria, e.g. for facade profiles

- Finding the best price around the world and global market research

- Cut lists for fixed length optimization, gating angle, surface treatment, allocation to assemblies and construction lots

- Identifying and establishing surface sizes and qualities

- Determination of material tolerances, hole and milling patterns, weld seam designs, glass specifications, edge processing, etc.

- Breaking down the material order quantities depending on the design types, delivery times and production or assembly sequences

- Material order codes for prefabricated parts such as laser cuts or sheet metal edge parts, turned and cast parts, complete assemblies and glazing

Priedemann supplies all planning documents for the construction of the planned facades. We familiarize ourselves with the potential of the respective production site and capacities and monitor the entire manufacturing process right through to the supply of materials on the construction site. The CAD and CAM data generated by us makes our clients ready for industry 4.0: This is how we bring the design directly to the machine!

- Preparation and provision of construction drawings (Working Drawings)

- Compilation of all documents from the shop drawings with the production drawings and installation drawings, the static and structural-physical calculations right through to the material lists

- Supervision of production on site, inspection of the production site, provision of a detailed inspection report with indication of differences to the planned execution, development of proposals for solutions

- Industry 4.0: Online data transfer, CAD and CAM plans for automated production

- Analysis and optimization of material flow and transport locally within the production site and on the construction site

- Identification of individual parts with allocation to individual production lots according to quantity, size and design

The quality assured during manufacture and production is to be maintained continuously on the construction site. To do this, we coordinate the correct sequence for an efficient assembly process. Priedemann thinks through all steps and interfaces, creates clear installation and assembly instructions and pays attention to interfaces with other trades.

- Specification of the assembly and logistics sequence

- Installation and assembly drawings (Installation Drawings)

- Preparation for the installation and information on the individual elements and parts

- Preparation of installation plans as well as plans for subassemblies and fixings

- Creation of separate drawings for components to be integrated, such as sun protection, revolving doors, etc.

- Assembly documentation

With the final phase of the project, Priedemann coordinates the handover of the completed facade to the client. For us, this includes a joint inspection tour on site as well as clear documentation of the finished facade, a comprehensive operating manual with corresponding explanations and drawings and a final meeting with the client.

- Acceptance tour with the team consisting of the client, architect and project management

- Final report on the basis of an on-the-spot inspection of further observations, recommendations and explanations

- Final meeting with the client’s representative with presentation and explanation of the report

- Preparation of the As-built Drawings, the documentation of the facade that was actually built

Specials

Facades have to cleaned and maintained. What sounds trivial is a component of facade planning and maintenance, which ensures the long-term value of a project, so it should not be underestimated. Priedemann keeps operating costs low by making the logistics of maintenance and cleaning an integral part of the planning right from the start. This is not only about equipment for maintenance and cleaning, the type and design of the facade itself can make a decisive contribution. Facade solutions that do not take this into account during planning and construction make maintenance more expensive over the entire service life.

- Moving components: Facades today contain a large number of movable and electrical components. Individual components require regular maintenance. This needs to be taken into account right from the start.

- Glass: Glass can be damaged, replacing glass must be possible at any point with reasonable effort. Today, individual panes weigh several hundred kilos, floor-to-ceiling triple glazing weighs up to one ton and more. We plan the right solutions for this.

- Cleaning: Glass cleaning and the cleaning of horizontal surfaces are part of regular operating expenses. We provide simple, secure access with as little technical effort as possible. We make cleaning recommendations and create complete cleaning plans right up to the choice of cleaning agents and necessary intervals with which cleaning can be carried out most effectively.

- Facade development: We plan all facilities for the development of the facade areas, determine the loads of fall protection systems, walkways and access systems and consider the points of contact and passage through the facade to the building shell during planning.

Memberships

© 2022 Priedemann