Architectural Competitions

Refurbishment

Feasibility Study

Project/Peer Review

Project Objectives and Brief

Concept/Schematic Design

Detailed/Developed Design

Technical/Construction Design

Specification/Tender Documentation

Tender Evaluation

Design Compliance Control

Mock-Up Association

Execution Compliance Control

Handover, As-Built Documentation

Variation Claim Evaluation

Monitoring

Defect and Failure Investigation / Expert assessments

deen

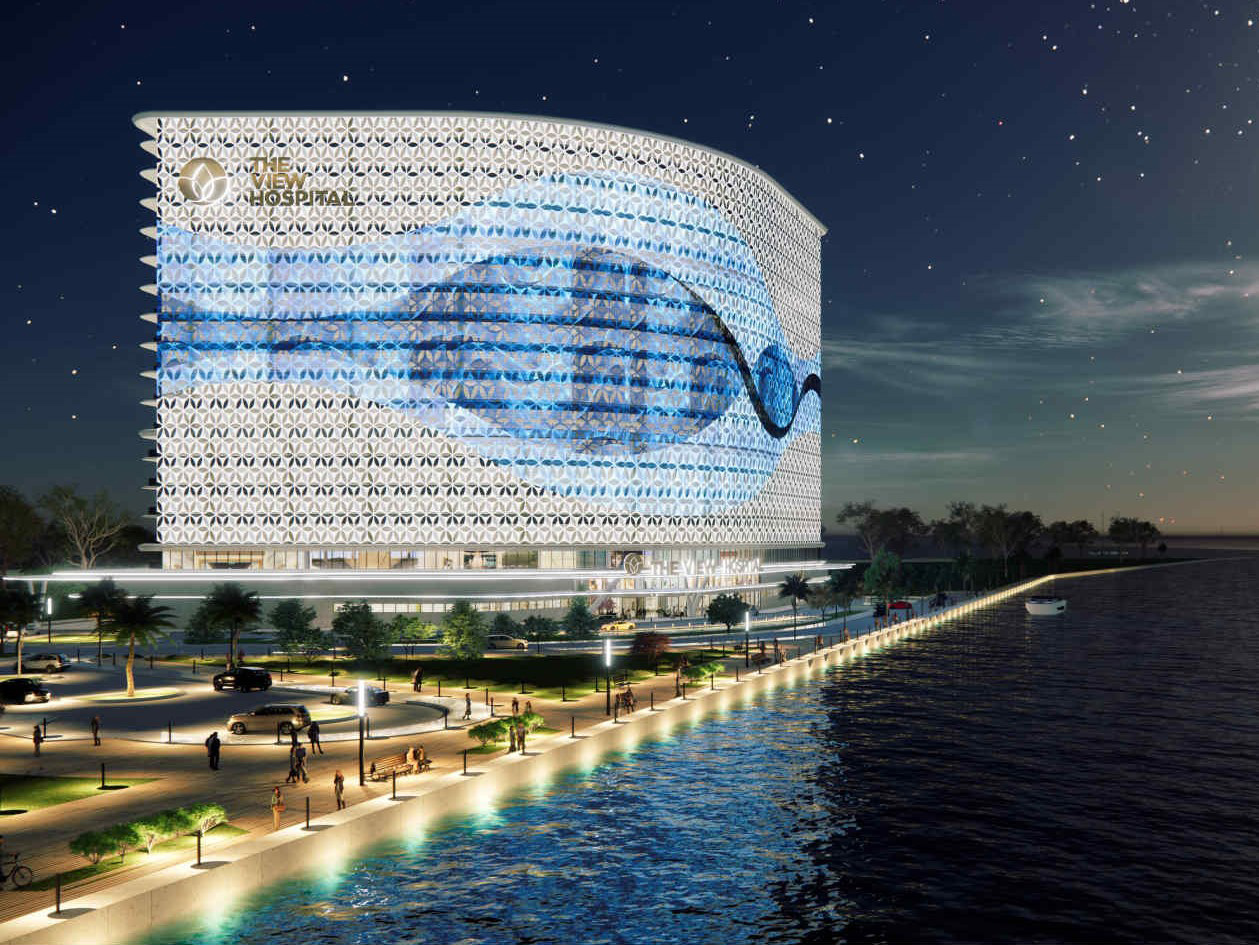

The View Hospital, Doha

Profession Aluminium Company

Owner / Developer

Assets Real Estate Development Co. W.L.L.

Architect

Lacasa Qatar

Building Function

Hospital

Status

Under construction

approx. 18,000 m²

Height

approx. 70 m

Technical Features

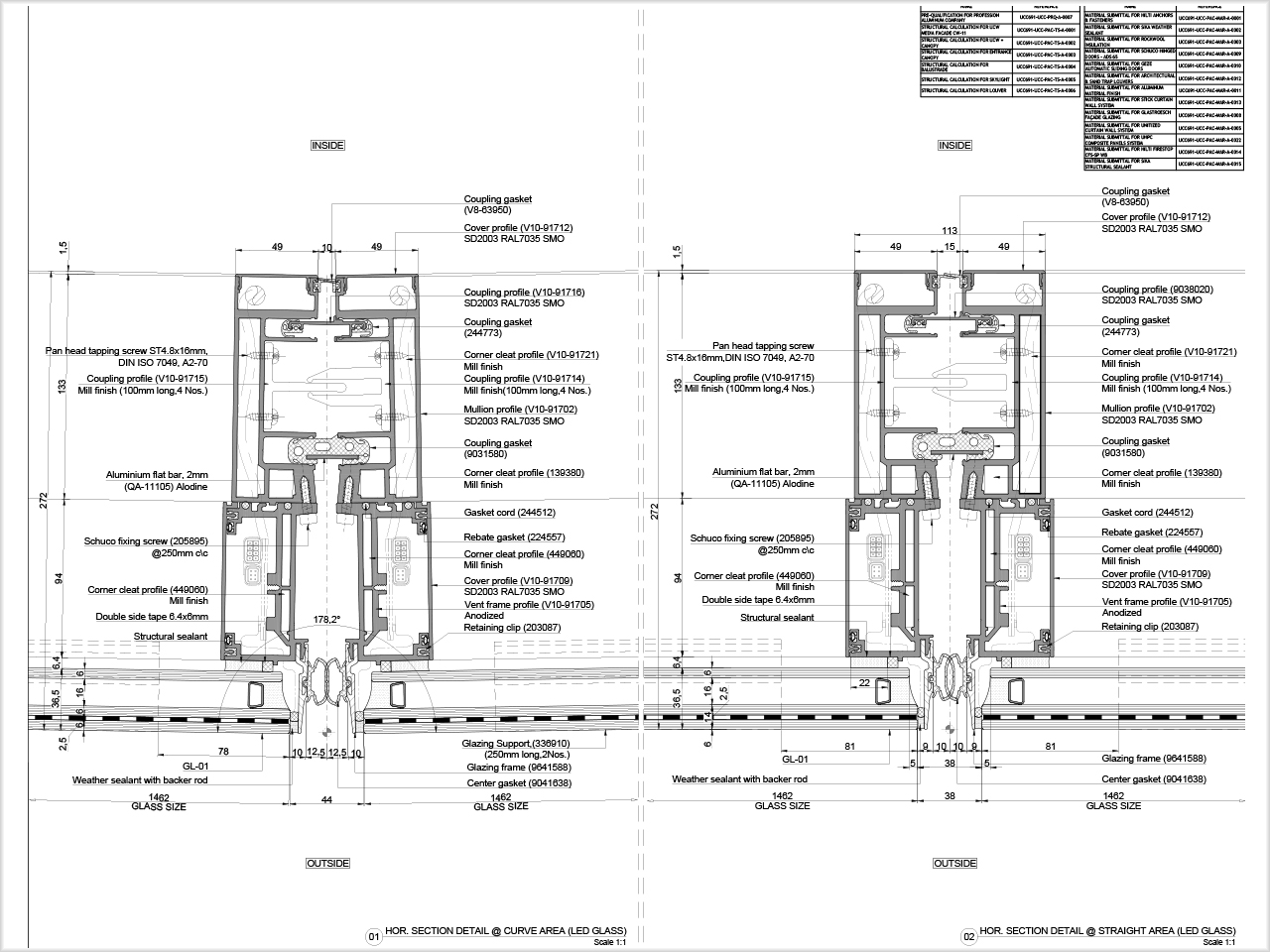

- Unitized curtain wall panels

- Media facade integrated into Unitized curtain wall

- Unitized curtain wall, glass fibre reinforced concrete

- Stick curtain wall system

- Steel add-on curtain wall system

We provided

Engineering

With the award of the contract, we check the contractual framework conditions as the basis for the implementation. If necessary, we adapt the technical solutions to any requirements that have changed – always with the goals of our client in mind.

- Contract review, determination of the contracted services and if necessary, developing alternative solutions

- Operational management, cost and budget audits

- Assessment of technical amendment suggested by the contracting parties, assessment of proposed modifications

- Evaluation of implementation alternatives to the approved diagrams (IFC Issued for Construction Drawings)

- Definition of the main strategic objectives as the basis for a coordinated facade design

Priedemann stands for system and facade concepts that think ahead with detailed solutions and technical feasibility even before the contract is awarded, always keeping an eye on the project as a whole and maintaining the project’s design standards even after the contract has been awarded.

- Development of the constructional facade concept on the basis of an integrated procedure together with the developer’s design team

- Development of a technical plan for all of the different facade areas, types and elements

- Project-specific adaptation of existing facade systems, creation of bespoke project solutions

- Design of all typical details as the basis of the structural design plan

- Optimization of production, manufacturing and assembly for the best possible cost-benefit ratio

Climate, wind and weather – the reality for a design is always tougher than the theory. Especially with innovations and customer-specific solutions, material and performance tests under real conditions are indispensable. The development of mock-ups and the coordination and monitoring of numerous load tests are central components of our services.

Architectural, visual mock-up (VMU):

Consultation with the developer for the design of a sample facade, on site or on Priedemann’s own premises, preparation of technical drawings and specifications, product and material research, preparation and compilation of factory and assembly drawings (assembly drawings, installation drawings), advice when selecting the most suitable manufacturer, coordination where adaptations are required

Test facade, performance mock-up (PMU):

Consultation with the developer for the design of a sample facade and the necessary test requirements, preparation of technical drawings and specifications, product and material research, preparation and compilation of factory and assembly drawings (assembly drawings, installation drawings), advice when selecting the most suitable manufacturer

On site facade test:

Consultation with the developer on on-site tests on the final elements or those actually installed, blower door test (test for airtightness), site camber test (on-site load test of a defined section of the realized facade or facade mock-up for air and water permeability and structural loads)

In addition to careful planning, the quality of the products and materials used is decisive for how well a facade performs and how long it lasts. Our knowledge is guaranteed and supported by our experience and application-oriented research in the Facade Lab. The exact definition of the materials to be used, their quality criteria and how they should be processed is part of our range of services.

- Preparation of the orders for all necessary materials

- Checking the technical data submitted for the materials

- Comparison of the materials proposed by the contractor with the specified materials

- Development of project-specific quality criteria, e.g. for facade profiles

- Finding the best price around the world and global market research

- Cut lists for fixed length optimization, gating angle, surface treatment, allocation to assemblies and construction lots

- Identifying and establishing surface sizes and qualities

- Determination of material tolerances, hole and milling patterns, weld seam designs, glass specifications, edge processing, etc.

- Breaking down the material order quantities depending on the design types, delivery times and production or assembly sequences

- Material order codes for prefabricated parts such as laser cuts or sheet metal edge parts, turned and cast parts, complete assemblies and glazing

Priedemann supplies all planning documents for the construction of the planned facades. We familiarize ourselves with the potential of the respective production site and capacities and monitor the entire manufacturing process right through to the supply of materials on the construction site. The CAD and CAM data generated by us makes our clients ready for industry 4.0: This is how we bring the design directly to the machine!

- Preparation and provision of construction drawings (Working Drawings)

- Compilation of all documents from the shop drawings with the production drawings and installation drawings, the static and structural-physical calculations right through to the material lists

- Supervision of production on site, inspection of the production site, provision of a detailed inspection report with indication of differences to the planned execution, development of proposals for solutions

- Industry 4.0: Online data transfer, CAD and CAM plans for automated production

- Analysis and optimization of material flow and transport locally within the production site and on the construction site

- Identification of individual parts with allocation to individual production lots according to quantity, size and design

The quality assured during manufacture and production is to be maintained continuously on the construction site. To do this, we coordinate the correct sequence for an efficient assembly process. Priedemann thinks through all steps and interfaces, creates clear installation and assembly instructions and pays attention to interfaces with other trades.

- Specification of the assembly and logistics sequence

- Installation and assembly drawings (Installation Drawings)

- Preparation for the installation and information on the individual elements and parts

- Preparation of installation plans as well as plans for subassemblies and fixings

- Creation of separate drawings for components to be integrated, such as sun protection, revolving doors, etc.

- Assembly documentation

With the final phase of the project, Priedemann coordinates the handover of the completed facade to the client. For us, this includes a joint inspection tour on site as well as clear documentation of the finished facade, a comprehensive operating manual with corresponding explanations and drawings and a final meeting with the client.

- Acceptance tour with the team consisting of the client, architect and project management

- Final report on the basis of an on-the-spot inspection of further observations, recommendations and explanations

- Final meeting with the client’s representative with presentation and explanation of the report

- Preparation of the As-built Drawings, the documentation of the facade that was actually built

Specials

Depending on requirements, Priedemann analyzes and calculates the static requirements of e.g. profiles, glazing and fixings in 2 or 3 dimensions or as finite elements. Evidence is provided on the basis of the applicable international or national standards.

- 2D construction analysis and detailed 3D analysis as needed

- Profile and glass structural specifications

- Calculation and analysis of finite elements

- Project structural analysis as documentation for the relevant auditors

- Structural evidence depending on the region based on EN standards or Eurocode, British Standards or American Standards.

The facade is the “face” of a building,a surface and a medium, which the building uses to communicate with its surroundings. The arrangement of open and closed surfaces, the materials used – all this reveals something about the interior life of a building and how it relates to its surroundings.

However, the metaphor of the “medium” can also be translated directly onto the facade by turning it into a “media facade”. Depending on the sharpness of detail and type of message, as well as the viewing distance, the facade surfaces differ in the size and number of pixels required. One of these pixels may be the size of a light-emitting diode or take up an entire facade or window element, depending on whether graphic animations, lifelike images, video sequences or texts are to be shown.

Priedemann plans all types of media facades and integrates them into the overall design. It is our aim that the media facade is part of the whole, including operation and maintenance, and is not reduced to the level of an appendage or a technical gimmick. For example, we develop concepts in which the energy needed to operate is generated by the facade itself. We take care of the necessary planning and performance data and create a feasible facade design. In the Facade-Lab area we develop transparent media facades together with industrial partners from the glass industry.

Memberships

© 2022 Priedemann